Reduce Energy Consumption

Recover Heat Energy from Industrial Exhaust Gases

Industrial processes produce immense amounts of heat energy, often wasted through exhaust gases. At Indeck, we offer an efficient solution that allows you to reclaim this energy and significantly reduce your energy consumption.

Indeck can accommodate a range of steam generation needs, with capacities ranging from 5,000 to 600,000 Ib/hr. Our technology enables high-pressure and high-temperature steam production, maximizing energy recovery for your operations.

Waste Heat Boiler Applications Include:

- FCCU

- Cement Kiln

- CO Gas

- COG

- Incinerators

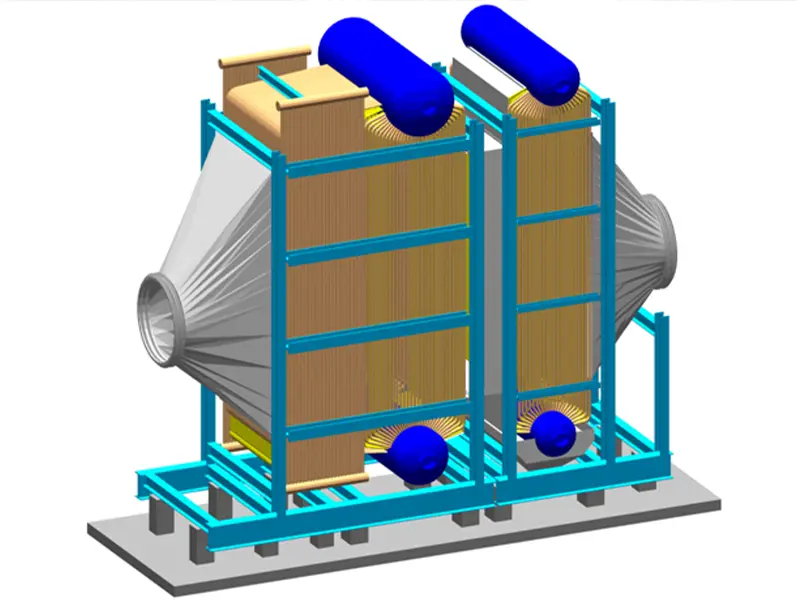

Harnessing Waste Heat

- Waste heat recovery from combustion turbines below 19MW

- Waste heat recovery from a variety of processes including refinery, petrochemical incinerator gases, thermal oxidizer gases, nitric acid process gases, fume incinerator gases, coking, FCC, cement kilns.

- Waste heat recovery steam generators utilizing shop assembled or modular field construction.

- Waste heat recovery steam generator utilizing extended surface (finned tube), and non-extended tube (bare tube) designs.

- Dirty gas applications equipped with soot blowers and or hoppers: Charcoal furnace exhaust steam, cement kiln exhaust, acid sludge gas, and ash-laden exhaust streams.

For examples of our waste heat recovery boilers see the Indeck Keystone-Energy site.

Indeck Solutions, Systems, & Services

At the heart of our commitment lies the dedication to providing our customers with the power they need, precisely when and where it matters most. With an extensive background in the industry, unwavering stability, and formidable financial strength, we possess the capabilities to deliver comprehensive solutions to any challenge. As a leading provider in the industry, the Indeck Group stands as a singular source supplier of cutting-edge boiler systems, recognized among the foremost manufacturers of industrial steam boilers in the United States. Our portfolio encompasses tailor-made boiler systems and a wide range of industrial steam boilers available for both purchase and rental. To inquire about steam boiler rental, please contact us at 847-541-8300 or explore our product line below

An Engineered System to Reduce NOx Emissions

The I-SCR System was designed by Indeck to help reduce the emissions of nitrous oxide (NOx) on industrial boiler systems. This system uses a selective catalytic reduction process that converts nitrous oxide emissions in the combustion flue into harmless nitrogen (N2) and water (H20) without forming secondary pollutants.

Burner Management and Combustion Controls

Nearly half a century of field experience in packaged industrial boiler systems has led to the development of our burner management and combustion control systems. Our in-house engineering, UL listed panel shop, and large component inventory allow us to develop custom systems very quickly.

Emergency Trailer-Mounted Deaerators

We provide emergency water treatment trailers for many purposes including use with rented boiler systems, in-plant deaerator inspections, and equipment expansion or replacement. Our trailer-mounted deaerators will meet your flow rate and water quality requirements to keep the plant on-line.

Boiler Accessories

We understand the importance of properly integrated accessories to complete industrial steam boiler systems. Our engineering staff ensures that the required interface is in place so that the overall boiler system performs at optimum efficiency.

Boiler Parts

At Indeck, our top priority is to keep our customers up and running at maximum efficiency. We have over $25 million worth of boiler parts in stock to help reduce downtime as well as improve and maintain the efficiency of your boiler system and accessories.

Indeck 24/7 Emergency Boiler Rental

With Indeck, you can trust in our ability to swiftly address your emergency needs and provide the necessary power solutions, keeping your operations running smoothly and minimizing downtime. Count on us for prompt and dependable assistance with all your emergency and power requirements.